Acoustic Metal Cladding

Acoustical characteristics determine how materials react to sound waves. It is well known that when there is a disturbance in a body of water, waves develop and move in all directions away from the disturbance. Air is a fluid that generates airwaves that move in all directions in response to disturbances. Airwaves are pressure peaks and valleys that may be sensed as air pressure oscillations at a particular frequency. When the frequency of these oscillating airwaves is between 16 and 16,000 hertz, the human ear interprets them as sound (16 kHz).

Mechanical longitudinal waves are used to transmit sound waves through a material medium. If a substance has any degree of elasticity, it can transmit sound waves (elastic bonds between molecules). This is true for the majority of materials. As a result, sound may travel through gases such as air and liquids.

A mechanical disturbance, such as turning on a machine with moving components that cause the air to vibrate at a specific frequency may produce sound waves. These air vibrations are sound waves that move in all directions. Because of the fluctuating air pressure, these sound waves will hit our eardrums and cause them to vibrate at the same frequency if we are standing close. The vibrations in the eardrums are detected by the human ear, which sends these vibrations to the brain as nerve impulses through the inner ear. We hear sound when this occurs. This process also implies that sound waves must travel through a medium (gas, liquid, or solid) between the source and the reception (the machine and human ear) to be produced and communicated. As a result, sound cannot exist in a vacuum.

In This Article

Acoustic Metal Panels

When it comes to sound absorption goods, metal is not typically the first material that springs to mind. Still, when metal is coupled with state-of-the-art acoustic materials, the results are exceptional in terms of both the acoustic performance of metal cladding and its aesthetics.

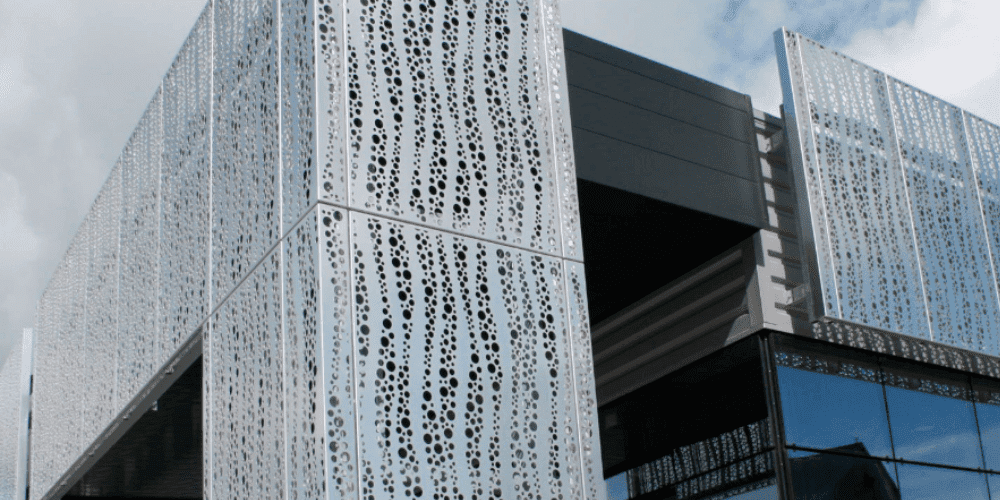

Acoustical metal panels have excellent sound absorption properties and may be used in various environments and applications. The perforated metal acoustic panels are durable enough to endure harsh industrial settings while still looking good enough to blend in with the high-end decor. Restaurants, airports, music halls, workplaces, retail, industrial facilities, and many other locations benefit from these cost-effective and simple-to-install alternatives. We provide a graphics option to personalize panels for an even more distinctive noise reduction solution, enhancing aesthetic enjoyment even more.

Applicability spectrum

By using metallic construction to create an enclosure (hood), a barrier, or a screen, it is possible to achieve sound attenuation or sound insulation while restricting the increase in noise level amplification on one side but not on the other of the acoustic protection barrier.

- Acoustic claddings with one absorbing face are highly appropriate.

- In the case of a primary wall effect or a double wall effect that is wanted (adjustable according to the constitution of panels)

What Is Acoustic Cladding, And How Does It Work?

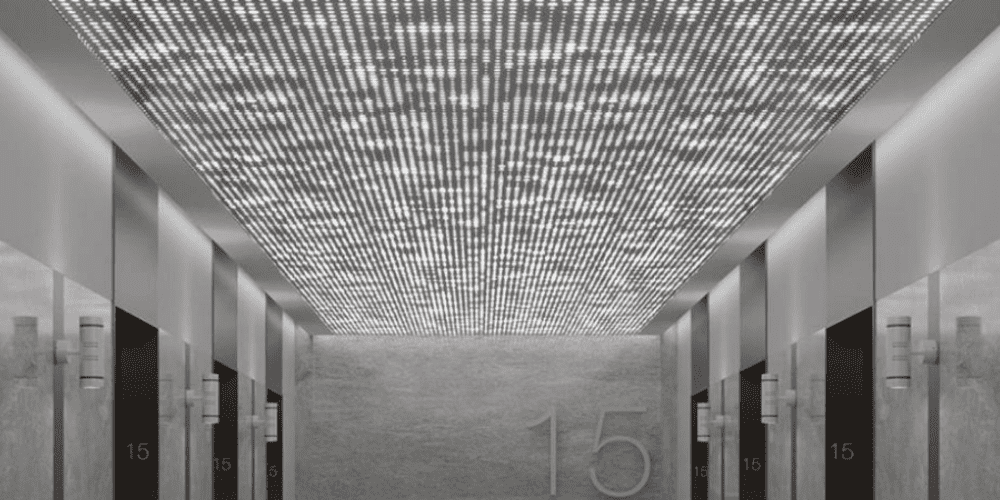

Acoustic solutions are becoming more popular, and you will discover various options, including acoustic panels. Acoustic baffles hung from the ceiling are only one kind of acoustic treatment. If you are experiencing acoustic issues in your office, studio, or meeting space, there are a variety of different options open.

Acoustic panels are sound-absorbing panels that are used to reduce background noise, reverberation, and echoes in a room or environment by absorbing sound. An acoustic panel is used in the broadest meaning when discussing acoustics and includes vertical and horizontal panels.

When it comes to sound management, perforated metal may be an essential component. But how does it function? How architects and designers utilize perforated metal to control noise, as well as some of the main advantages of specifying perforated metal for acoustic applications, are outlined hereunder:

Using Perforated Metal In Acoustics

To reduce sound and noise in residential, recreational, and commercial buildings, perforated metal is often used as ceiling panels, wall cladding, screening, and architectural façade.

Each panel may be configured to absorb, reflect, scatter, or block off specific frequencies depending on the acoustic problem.

Tips Using Perforated Metal In Acoustic Metal Cladding

Sound Absorption Using Perforated Metal

Perforated metal serves as a protective and acoustically transparent covering for acoustic material while absorbing, reflecting, or dispersing sound. Because the acoustic material is responsible for noise management, the perforated metal must be transparent to sound waves to reach the substance behind it.

When utilizing perforated metal in this manner for acoustics, it’s critical to choose a hole pattern and material that provides the most sound transparency at all frequencies. This is usually a perforation pattern with many tiny, closely spaced holes to enable the most amount of sound to flow through.

Interiors may benefit from this kind of treatment. When ambient sound management is required, it is frequently found in businesses, hotels, stadiums, schools, recreational centers, and industrial work settings. Perforated metal may also be used as external cladding to prevent outdoor noises by architects.

Managing Frequencies Using Perforated Metal

Perforated metal is not needed to be transparent if you want to cut out or decrease a particular issue noise. Still, it does play an active role in acoustic management through a resonant sound absorber.

The holes in the perforated metal panels interact with a layer of trapped air in this kind of application to focus the absorbed sounds into a specific frequency range. Low-frequency sound absorption is quite effective with these systems

The Benefits Of Perforated Metal In Acoustics

Aluminum and stainless steel are the most popular materials for the perforated metal in acoustics because they maintain strength even when perforated in the smallest profile. Perforated metals have many advantages in acoustics:

- Perforated metal is a satisfying answer to sound issues since it comes in various patterns and finishes, including powder-coated, coloured, and metallic coatings.

- It has a broad range of perforation patterns, including holes of various sizes, shapes, and pitches.

- Perforated metal panels for acoustic applications, mainly architectural, may be folded to provide ornamental visual appeal while reflecting or controlling noise.

- It is long-lasting and straightforward to maintain without affecting the acoustic material’s function.

Insulation And Acoustic Absorption Are Not Synonymous

Acoustic insulation, which is usually accomplished by installing solid boards when the structure is built, may decrease echo and sound pollution from the outside or from one room to the next. As a result, acoustic panels aren’t the best choice for insulating areas subjected to external noise pollution. Their primary function is to absorb sound that enters the room.

Problems

The materials used in the building’s construction, such as glass, concrete, or metal, may cause sound reverberation. It may also be the result of a furniture shortage.

Correcting the sound reverberation in a space may enhance auditory and health comfort. With the development of open spaces, sound problems in professional spaces are becoming increasingly common.

Resonance

As a result, there are several ramifications that you should be aware of. When noise and voices are loud, sound reverberation produces an unpleasant noise sensation.

When Is It Appropriate To Use Acoustic Metal Cladding?

The primary advantage of enhancing the acoustics of a space is that it improves the inhabitants’ well-being and acoustic comfort. When a room’s echo or sound resonance is too powerful, acoustic panels are employed. This may be because of the building’s construction elements (glass, concrete, or metal) or simply because the décor is too simple.

Sound that echoes may create the appearance of distracting background noise because the loudness of the sound has increased. Excessively high resonance rooms cause irreversible loss of intelligibility, causing fatigue and lack of focus in its inhabitants. If done correctly, acoustic metal cladding is instantly effective regardless of the area in question.

The Final Word

Acoustic metal cladding absorbs sound, which helps to decrease reverberation levels in a confined area. The sound-reflecting surface is reduced in reflectivity. Surface perforations enable sound to be absorbed by acoustic backing materials via the surface of the material. By doing so, you may minimize unnecessary background noise, improve communication and attention, and reduce stress.